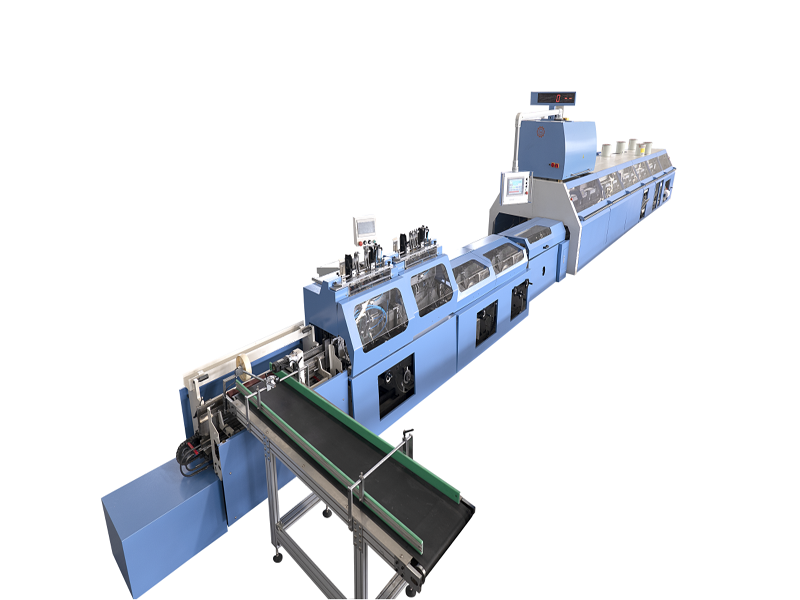

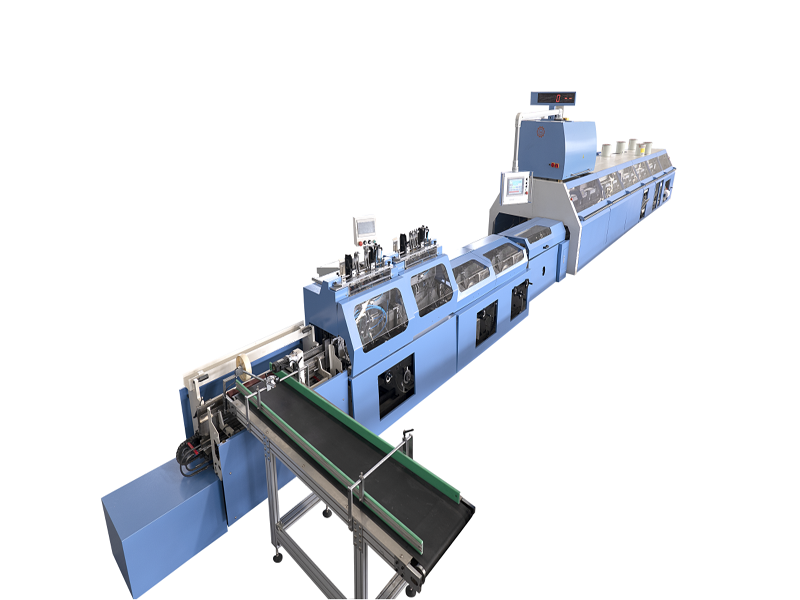

New design concept:

The AUSCP SL70 High-Speed Backgluing and Backlining Machine is the 7th generation product independently researched, designed, and manufactured by Dongguan Yasi Mechanical Equipment Co., Ltd. With a production speed of up to 4,200 books/hour. The machine design overturns the traditional synchronous belt conveyor, instead opting for a new one-book, one-clamp design philosophy, ensuring that books are neatly and uniformly placed, completely eliminating the possibility of loose or misaligned book bindings that frequently occur in traditional models. The product performance reaches the top tier of book blocks processing and shaping machines.

Product composition:

The AUSCP SL70 High-Speed Backgluing and Backlining Machine adopts an integrated design, incorporating functions such as automatic book blocks conveyance, double-side paper lamination (optional), glue application (compatible with both cold and hot melt glue), packaging back paper, support tower pressing and shaping, infrared-enhanced drying system, etc.

Functions & Features:

● Electrical Control System: The system is implemented through photoelectric detection for online control, with the entire line adopting linked conveyance. Simply placing book blocks in the machine, the whole production process will be automatically completed. With the human-machine interface touch panel, switching specifications are more efficient, straightforward, and effortless. Main driving parts and electrical components are made of imported materials, durable, and cost-effective.

● Book blocks Conveyance: Lock-threaded book blocks are placed in conveyance mechanisms, which are then conveyed by preset speeds.

● Book blocks Vibration: The machine features a function whereby the book blocks vibrate to align and conveyed, letting off all the air in between and ensuring a flat surface.

● Double-Side Paper Lamination: Add lamination paper to the feeder, and the machine automatically completes the front and back protective covers via the circulating adhesive device. The adhesive ensures that the resulting attachment is strong and reliable. This feature allows a reduction in workforce by 2-3 persons, lowering costs and increasing productivity.

● Book blocks Conveyance Lamination: Features 30 clamps, with each book blocks having a designated clamp. This cyclic system ensures uniform and flattened book blocks are firm and consistent.

● Glue Application: The machine uses hot melt and white latex function. Includes 1 set of hot melt furnace, 2 sets of white latex furnaces, and 1 set of side glue furnace.

● Drying: The machine has a hot air function and an infrared long-distance heating function, energy-saving and environmentally friendly.

● Wrapping: Allows for the automatic packaging of book blocks, and automatically cuts reel paper to the desired width. The machine also features automatic gluing, automatic fitting, support tower pressing, shaping, and a solid, aesthetically pleasing back cover structure.

● Pressing and Shaping: It adopts the latest tower clamp design, which provides a strong compression force, strong product forming and aesthetic appearance.

● Can form a complete book block processing line with a three-sided cutting machine, completing high-precision book blocks cutting and outputting to subsequent workstations

Technical Data:

Max. operating speed

|

70 book blocks/min |

Power consumption |

26.5 KW |

|

Max.book block size |

460×300 mm |

Standard voltage

|

30kw 380V 50Hz |

Min.book block size

|

148×100 mm |

Air consumption (external supply) |

0.35 m3 /min 8 bar |

Thickness of book block

|

3-60 mm |

Max.pressure |

100 KN |

|

Thickness of book block |

60-150g |

|

22800×3850×1735 mm |

|

|

120-300g |

|

10500 kg |

|

|

150℃ |

|

|

|

L H S

|

AUSCP SL70 |

|

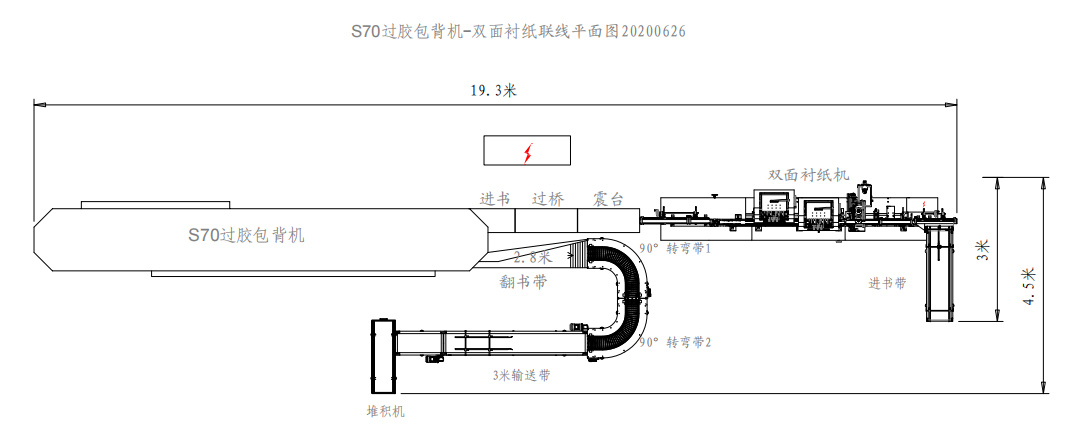

Equipment installation plan:

Introduction video