Product composition:

The Yasi Digital Automatic Folding and Book-Sewing Machine is a 3 in 1 combined production line solution. It includes the paper stacking system, electronic paper feeder system which is known as paper separation system, conveying system, folding system, book sewing feeding system, book sewing system, and automatic control system.

Functions & features:

Folding machine:

● It adopts the most advanced paper separation and feeding system, which can continuously complete the folding and sewing of a book according to the page numbers for mass production.

● High folding speed: The folding speed can reach 220 meters per minute, with reliable and stable paper feeding without compromising cosmetics. The folding rollers adopt new technology, with strong paper gripping force, rust resistance, and ink adhesion.

● High folding accuracy: It can safely transport paper, achieving high accuracy and excellent production efficiency.

● Intelligent control: The electrical system adopts microcomputer control, a color touch screen, and monitors the entire process of paper feeding, conveying, multiple feedings, and missed feedings.

● Fault detection & identifying: When faults such as missing signatures, multi-signatures, jams, dropped signatures, shortened signatures, and broken signatures occur, the machine will alarm and pause while displaying the fault.

● Memory storage: can store multiple book sewing programs and recall them as needed.

● Miss signature detection system (optional).

Book sewing machine:

● High speed and precision: maximum speed of up to 160 signatures per minute. The book signature on the saddle is precisely positioned through synchronized belt structure with a puller.

● Intelligent control system: Colored touchscreen monitors the entire production including paper feeding, conveying, lockstitching, and receiving, ensuring the quality of lockstitching.

● Fault detection & identifying: When faults such as missing signatures, multi-signatures, jams, dropped signatures, shortened signatures, and broken signatures occur, the machine will alarm and pause, while displaying the fault.

● Automatic mis-signature detection function (optional).

● Memory storage: can store multiple different book sewing programs and recall them as needed.

● Automatic plate adjustment: by setting the size of the signature on the touch screen and confirming the page-turning method, the transmission system automatically positions the conveyor belt, adjusts the position of the fixed saddle drive chain and acceleration wheel, and adjusts the height of the finished book platform. Simple and easy to learn, fast operation, and quick plate switching, which improves production efficiency.

● Signature conveying: the signature is placed on the conveyor belt after being turned and is pushed by the conveyor chain. The acceleration wheel pushes the signature into the active lockstitch saddle, and the speed of the acceleration wheel is automatically adjusted according to the speed of the machine.

● Automatic signature separation and thread cutting: the automatic signature separation and thread cutting device (cuts the excess thread to about 8-10mm for easy binding) can separate the book signatures one by one according to the setting, regardless of the number of signatures in the book to avoid damaging book spine.

● Flat and Cross Locking: The use of fine ultra-short needles (ø1.6mm) and close needle spacing (19mm) for locking results in a flatter and firmer stitching, which is less prone to glue leaking. The locking device is composed of a cam-style equipment unit, which not only reduces noise but also increases the durability of the cam. Flat or cross locking can be selected based on customers’ needs.

● Positioning Baffle Alignment: When signatures enter the sewing unit, the positioning alignment baffle swiftly moves in the opposite direction of entry, aligning any misaligned sheets to ensure the sewn book block is neatly aligned.

● Lubrication on demand: equipped with centralized oil supply lubrication system, oil pressure alarm and oil storage device. When the machine is in operation, lubricant is precisely supplied through the pipe to wherever necessary in a timely manner.

Technical Data:

(Collating machine):

|

|||

|

Max. operating speed |

220meters/min |

Paper folding weight

|

40-200g/㎡ |

|

Max. printing sheet size |

640×420mm |

|

400kg |

|

Min. printing sheet size |

200×150mm |

|

600mm |

|

L H S

|

|

|

(Book sewing machine):

|

|||

|

Max. operating speed |

160signatures/min |

|

2 Signatures |

|

Max. signature size (H x L) |

420x320mm |

Thread hook diameter

|

¢1.6 mm |

|

Min. signature size (H x L) |

150x100mm |

Max. number of stitch positions |

10 |

|

Stitch lenght |

19 mm |

|

0.5~3mm |

|

L H S

|

|

|

(Whole machine):

|

|||

|

Power consumption |

5kw |

|

max. 1.0m3/min at 8bar |

|

Net weight |

3500Kg |

Dimensions (length x width x height)

|

5100×1900×1850mm |

|

|

Standard voltage |

380V/ 220V 50Hz三相

|

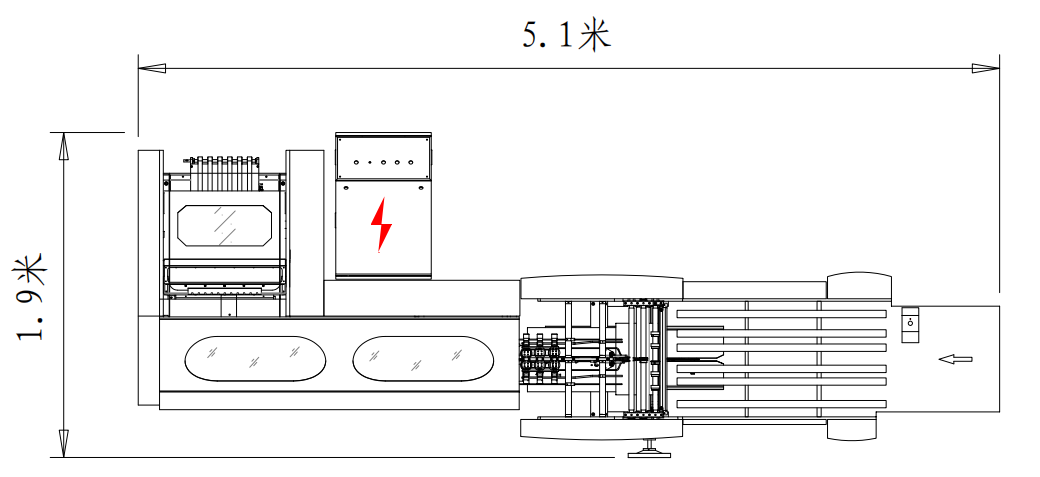

Equipment installation plan:

Introduction video