Product Composition

Composed of a backpack paper feeding mechanism, a 4-grid folding system, three independent servo-controlled folding knives, and a booklet collector.

Purpose

The machine is engineered for folding single sheets of various types, including booklets, pamphlets, instruction manuals, and letters. It features a stack feeding system and employs a hybrid folding technique, using four buckle plates and three knives. When using the buckle plates, the machine can perform parallel, accordion, and roll folds. During hybrid folding, the machine executes vertical, mixed four-fold patterns, and the folded sheets are collected and stacked by the sheet collector. The machine is configured for 32-page regular or reverse folding.

Features and Functions

● Intelligent Control System: The electrical system utilizes imported components and control systems. A PLC (programmable logic controller) manages the operation, while a variable frequency drive regulates speed.The folding knives are driven by imported servo motors and drivers, ensuring high precision and simple maintenance.During operation, the machine monitors for double feeding and paper jams. Faults are displayed on the human-machine interface via an operator dialogue terminal, simplifying operation and accommodating various paper types within its operating range.

● Fault Detection and Protection: The paper feeding system has double-feed detection that automatically stops feeding when a double-feed is detected.If a paper jam occurs in the grid or at the folding knives, the fault detection system will automatically halt the machine.

● Stack Feeding: The stack feeder enables continuous sheet feeding, with automatic sheet separation by air blowing, improving production efficiency.

● Threaded Folding Rollers: The folding rollers use imported polyamide adhesive strips combined with specially manufactured steel threaded rollers. This design offers durability comparable to imported rollers and increases the paper gripping area by 75% compared to traditional straight-thread rollers.

● 32-Page Normal and Reverse Folding: The machine supports both 32-page normal and reverse folding and can resolve layout issues32-Page Proper/Reverse Folding Function:

The machine is capable of both 32-page proper folding and reverse folding, effectively resolving imposition (layout) challenges.

● On-Demand Lubrication: A centralized oil supply lubrication system is provided. It features: An alarm for low oil pressure.A timed and metered lubrication device that, during operation, delivers precise amounts of lubricating oil through dedicated lubrication channels to the necessary points.

● Paper Transportation: The system uses three-hole wide polyurethane suction wheels (designed to prevent suction marks) to pick up individual sheets from the paper stack, convey them to the paper transfer board, and complete lateral positioning during transport.

● Suction Wheel Paper Separation: A vacuum suction wheel controls paper feeding, complemented by a ball-rolling mechanism for paper positioning. Special polyurethane vacuum suction wheels ensure that even sensitive papers remain scratch-free.

● Perforating and Creasing: During the folding process, additional operations such as perforating and creasing can be performed as required.

● Counting Function: An optical sensor counts sheets cumulatively and allows for batch count settings and control throughout machine operation.

● Ruler and Digital Display: All adjustment points on the machine are equipped with rulers and digital display devices, facilitating precise and quick adjustments.

● Selectable Grid Folding Function: The grid plate is fitted with a swing-type paper turning device that quickly selects the appropriate folding grid. This enables the machine to perform various folding types—such as parallel, accordion, or roll folds—with ease.

● Adjustment Data Display: All adjustment areas include corresponding rulers and displays, which significantly reduce the time needed for setup.

● Automatic Booklet Gathering: Once the folding process is complete, the finished booklets are automatically and orderly output using a standard paper collector.

Optional Equipment

Compatible with LSZ460A Vertical Flat Sheet Collector and LSZK360B Vertical Sheet Bundling Machine.

Technical Specifications

Maximum Paper Size for Folding |

780×1160 mm |

|

Minimum Paper Size for Folding |

Single Buckle Single Fold |

150×200mm |

Single Buckle Single Knife Fold |

200×300mm |

|

Single Buckle Double Knife Fold |

300×400mm |

|

Single Buckle Triple Knife Fold |

390×540mm |

|

Foldable Paper weight range |

40~200 g/㎡ |

|

Max.stacking height |

65mm |

|

First grid folding range |

55~645mm |

|

Buckle quantity |

4sets |

|

Vertical folding count |

3times |

|

Folding roller speed range |

75~210 m/min |

|

Maximum Frequency of Folding Knives |

350stroke/min |

|

Folding speed |

210×297parallel one folding27000 sheet/hr |

|

540×780 parallel one folding12000 sheet/hr |

||

General power:Three-phase five wire system |

三相五线制 380V 50Hz |

|

Control power supply: single phase |

单相220V AC 24V DC |

|

Electrical supply deviation |

±1Hz ±10%V |

|

Maximum machine power: |

7.14KW |

|

Total net weight |

3000 Kg |

|

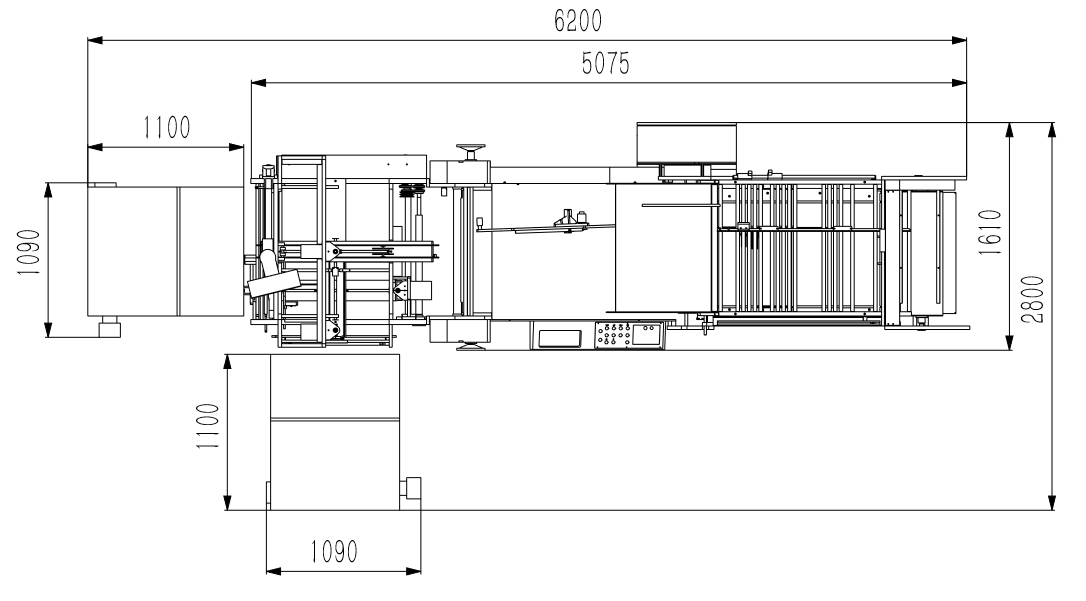

Equipment Installation Plan

Video Introduction