Prouduct Usage :

Process flow :

The process involves book block conveying, rounding the book block, backbone forming, applying glue on the spine, attaching gauze, affixing spine paper and headbands, casing-in, rounding the case, lining, fitting the case with the book block, conveying the book, creasing, pressing the book flat, and stacking.

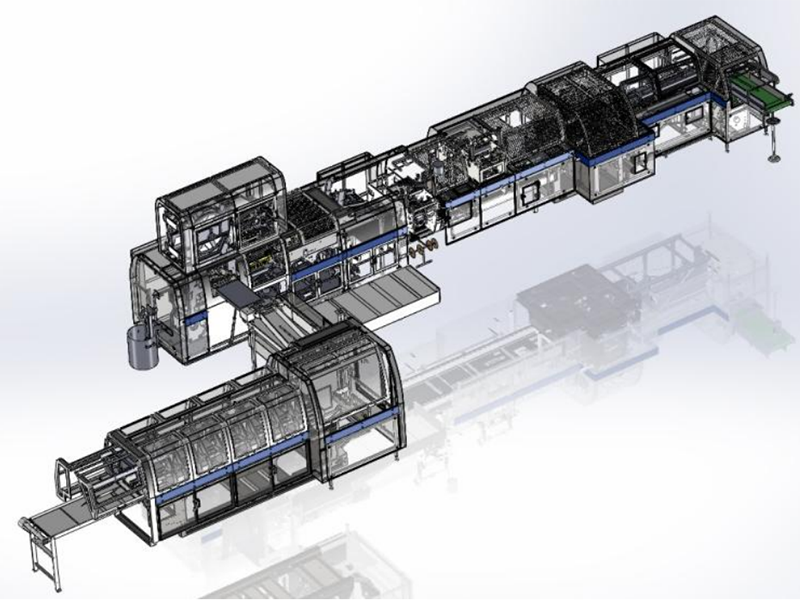

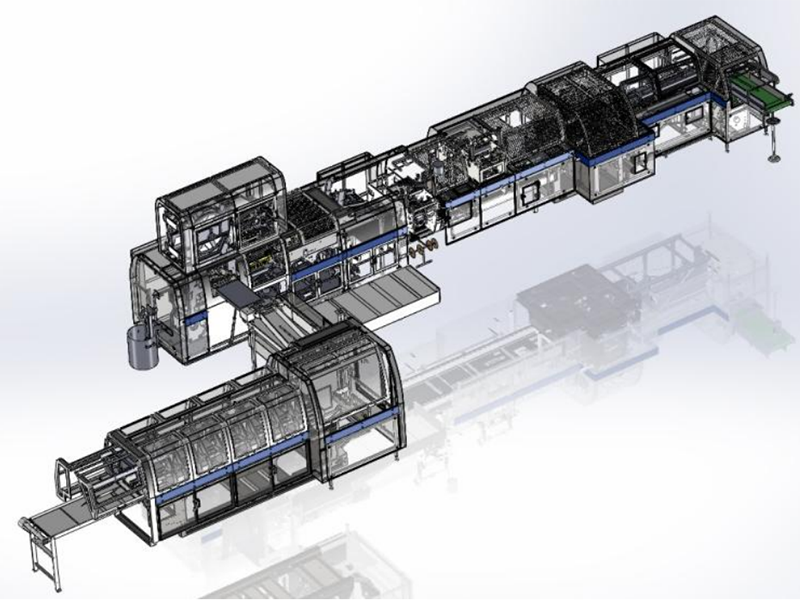

Product Composition :

The Hardcover Linkage Line consists of several units for book block conveying, rounding and backing, casing-in, creasing, pressing, and conveying. It is a comprehensive system for hardcover book production, featuring photoelectric monitoring for online control.

Product Features :

● Data Storage and Recall: Stores historical data for easy access; preset data can also be stored.

● Automatic Adjustment: Measurements or input of case and book block dimensions (length, width, thickness) enable the control system to automatically adjust operations based on book size.

● Automatic Adjustment: Measurements or input of case and book block dimensions (length, width, thickness) enable the control system to automatically adjust operations based on book size.

● Automatic Lubrication: The line is equipped with a timed and quantified lubrication system, ensuring major lubrication points receive oil during operation.

Technical Parameters :

|

360 ×270 mm |

Maximum case open dimensions |

135×100 mm |

|

Minimum dimensions of the book block |

125 ×100 mm |

Minimum case open dimensions |

210 × 135 mm |

|

Book block thickness |

4-60 mm |

Total power supply |

Three-phase,four-wire system 380V 50Hz |

|

Maximum mechanical speed |

50 books/minute |

Input power |

54 KW |

|

Compressed air requirements (flow and working pressure) |

traffic |

220 liters/minute |

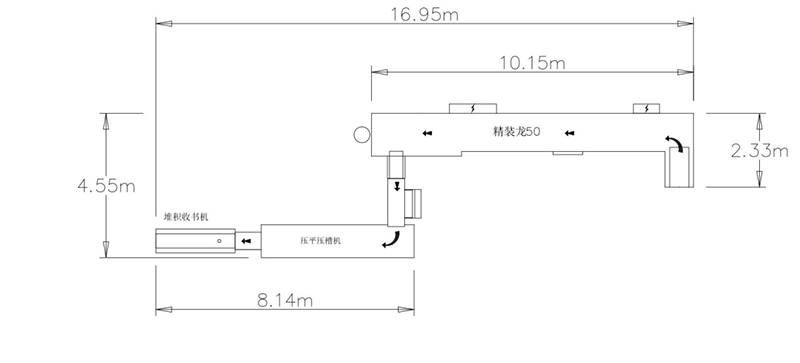

Dimensions (Length × Width × Height) |

16950×4550×2500 mm |

Working pressure |

8-10 bar |

Net Weight |

24800 kg |

|

|

L H S |

AYSCP JZL500 |

||

Equipment installation plan :

Video Introduction

Product Introduction of RK-50 Soft and Hard Leather Dual purpose Shell Machine :

Product composition :

Functions :

● Storage and Memory: The machine can store historical data for easy recall and allows for presetting and saving of new data.

● Automatic Adjustments: Users input the dimensions of the book core and cover (length, width, thickness) via a touchscreen. A servo drive system automatically adjusts nine parameters including the cover conveyor length and width, cover rounding, cover positioning, book core transport height, chain grip, and book core positioning in both width and length, ensuring convenience, precision, and high efficiency when changing specifications.

● Fault Detection: Alerts are issued, and the machine stops automatically upon any malfunction, with the fault displayed onscreen.

● Book Core Positioning:Individual book cores are fed into the conveyor chain, pre-positioned, and delivered to the positioning unit by a chain equipped with a delivery rod, which separates and accurately positions the cores.

● Gluing:After positioning, the book core is moved upwards by a lifting knife and passes through a rotating gluing roller. The textured rollers cater specifically to rounded spine gluing requirements.

● Cover Shaping:Individual covers are fed through the separation unit into the cover shaping area where they are flattened and rounded by heated rollers to achieve the required curvature.

● Cover Positioning:Shaped covers are pushed forward for precise positioning by the conveyor system.

● Casing-In:The glued book core and positioned cover are lifted to the casing-in unit, where the combination is completed.

● Book Collection:Completed books (notebooks) are released from the lifting knife and gently guided onto a conveyor belt for output.

● Automatic Lubrication:The machine features a timed and quantified lubrication system that ensures all major lubrication points receive oil during operation.

Technical Data :

书壳展开最大尺寸

|

630×365 mm |

书壳展开最小尺寸 Minimum Open Cover Size |

210×135 mm |

书壳厚度范围 Cover Thickness Range |

1-5mm |

书芯最大尺寸 Maximum Book Core Size |

270x360mm |

书芯最小尺寸 Minimum Book Core Size |

120x75mm |

总功率 Power consumption |

5kw |

最小幅面尺寸 (H x L) Max. number of stitch positions |

100×125 mm |

书芯厚度范围 Book Core Thickness Range |

4–60 mm |

最高机械速度 Maximum Speedh |

50 books/minute |

主电机功率 Main Motor Power |

33.5Kw |

整机功率 Total Power |

9.34 Kw |

电压要求 Voltage Requirement |

380v |

频率 Frequency |

50Hz |

机器外形尺寸(长×宽×高) Dimensions (L×W×H) |

48050×2115×2410mm |

机器净重 Machine Weight |

5500Kg |

RK-50 flattening and grooving machine product introduction :

Components :

Components:The machine includes a control system, pre-positioning mechanism, book pushing mechanism, book conveying system, book pressing unit, groove hot pressing shaping mechanism, book discharge conveying system, book collection unit, and a hydraulic system.

Features :

● Storage and Memory: Capable of storing historical data for easy access and allows for the presetting and saving of new data.

● Automatic Adjustments: Input the dimensions of the cover and book thickness via a touchscreen. The servo drive system automatically adjusts multiple parameters such as book conveyor length, book pressing thickness, groove depth positioning, and book handling, offering convenience, precision, and high efficiency when changing specifications.

● Fault Detection: The machine halts and issues an alarm, displaying the fault when a malfunction occurs.

● Book Entry:Books that have been cased by the casing machine are sequentially fed onto the conveyor belt, held in place by an electromagnetically controlled stopper.

● Book Positioning:After release by the electromagnetic stopper, books enter the flipping station spine down, guided into position on the support tray by a book pusher rod, with precise width positioning by the pressing rod.

● Book Clamping:A clamping mechanical hand, powered by the hydraulic system,sequentially feeds the books into the working position.

● Book and Groove Formation:The groove forming mechanism takes the books fed by the mechanical hand, performing six consecutive pressing and hot pressing cycles to shape the groove.

● Book Discharge:Finally, the discharge mechanical hand holds the finished books, placing them onto the discharge conveyor belt, completing the book shaping and creasing process.

● Hydraulic System:Provides the necessary power for book pressing and creasing, ensuring consistent pressure regardless of minor variations in book thickness.

● Automatic Lubrication:Features a timed and quantified automatic lubrication system, which ensures all major lubrication points receive oil during operation.

Technical Specifications:

书本最大尺寸

|

375×310 mm |

书本最小尺寸 Minimum Book Size |

135×100 mm |

书壳厚度范围 Book Thickness Range |

4-60mm |

最高机械转速 Maximum Mechanical Speed |

50 转/分钟 50 cycles/minute |

主电机功率 Minimum Book Core Size |

4kw |

整机功率 Total Power |

19kw |

电压要求 Voltage Requirement |

380V |

频率 Frequency: |

50HZ |

机器外形尺寸(长×宽×高) Dimensions (L×W×H): |

5780×2465×1755mm |

机器净重 Net Weight |

4200Kg |