The origin of thread locking machines originated in Europe and caused a good trend. Now after years of development, it has achieved a lot. Automation is a very important development trend for thread locking machines to get into work well.

Fast speed, good stability and high efficiency.

In order to meet the urgent demand for high speed in the post-press bookbinding industry, all manufacturers have adopted the latest modern design methods and technologies to design and optimize the mechanical mechanism of the thread locking machine, such as the folding part of the folding and turning pages, the positioning of the books in the thread locking part of the book, the book knocking device, the book clamping knives, etc. Especially the optimization and improvement of the cam curves have improved the stability and reliability of the various mechanisms. It is no longer difficult for the maximum speed of the thread locking machine to reach 200~220 posts/minute. For example, Aster's model 220SA and Martini's model 3214 can meet the production requirements of this speed.

Aster and Smyth companies produce lock-matching production line, can be in a process of continuous completion of the page and lock line (up to 3 sets of locking machine), after locking the core can be published by the automatic unloading system, immediately to the gluing machine or manual unloading table. Low investment, only one operator is needed, high efficiency and short production time of the lock-linking production line. The collator and the lock-linker are easily separated. The collator and the lock-linker can handle two different operations independently.

Automation with short adjustment lead times

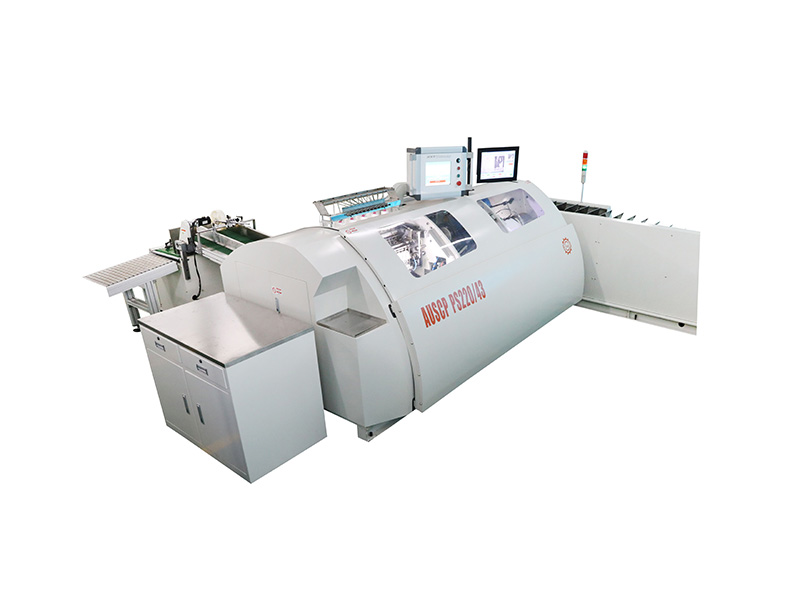

is an important trend in the development of automation technology for thread locking machines. With the increasing number of small, on-demand print runs, thread lockers need to be set up quickly, and start-up preparation time has become a very important measurement. Users are demanding tool-less start-up preparation, with all settings automatically adjusted by computer system programming. ASTER220SA thread locking machine, for example, as long as the length, width, number of folds, the number of posts in the control screen input bound booklet, the computer and PLC system can automatically adjust the thread locking machine booklet positioning device, cutter knife, clamping knife, conveyor belts and chains, the height of the output table, etc., and can be based on the size of the booklet, and can be adjusted according to the size of the booklet. It can also set the bottom needle according to the size of the booklet to minimize the adjustment time.

With excellent stability and performance, the wire locking machine is a very important machine for binding all kinds of solid books well, and thick books can also complete the job. Durable, performance is greatly improved and quality is guaranteed.