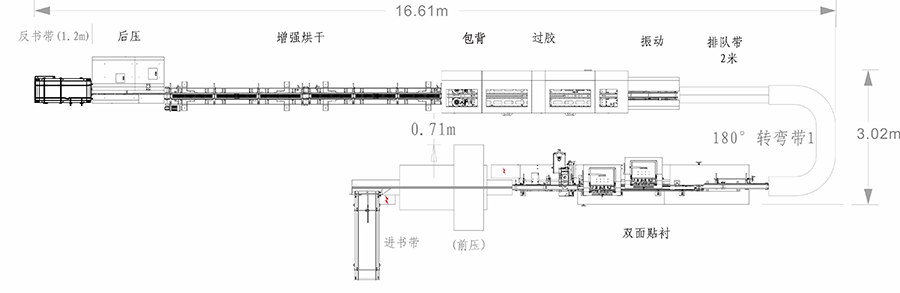

Equipment installation plan :

Product composition:

The AUSCP SL60 is a fully automated production line for hardcover book blocks that includes book blocks delivery, front pressing, dual-side pasting, glue drying, book spine wrapping, enhanced drying, dual-side pasting again, rear pressing, and secondary book collection structures. Online control is implemented through photodetection. The machine features an integrated design that only requires the insertion of book blocks; the machine then automatically delivers them. The machine also features a color English/Chinese interface control panel for fast and easy operation. Its main drive parts and electrical components are made of imported materials that are durable and cost-effective.

Functions & features:

● Book blocks delivery: Insert locked book blocks into the delivery mechanism, and the machine will automatically deliver them at a set speed.

● Front pressing: Press the front of the book blocks to flatten its back and eliminate any air pockets between book covers, making the covers smoother.

● Dual-side pasting: Adhesive laminate the dried book blocks by delivering it to the dual-side pasting machine, making it firmly bonded and reliable. The machine can be linked with any book spine gluing machine for automatic feeding, circular gluing, and optimal adhesion, and it features an automatic glue-loading device that prevents the glue from hardening.

● Book blocks vibration: The production line features book blocks vibration that transmits each book blocks evenly, which let the air out so signatures can be pasted firmly and smoothly.

● Glue drying: Automatic gluing and glue drying is used, and the amount of glue can be adjusted by adjusting the scraper gap to maintain stable adhesive volume and adhesive strength.

● Enhanced drying: By controlling the evaporation of water from the glue at the back of book blocks to achieve the best adhesive viscosity and strength. The machine features four stages of hot- air drying and two stages of cold-air drying.

● Rear pressing: Press the back of the book blocks for better adhesion between the back of the book blocks, book covers, and endpapers.

● Bookspine wrapping: Used for high-quality binding of notebooks, account books, etc., this machine features an adhesive-coating mechanism, a spine-wrapping mechanism, a split-book mechanism, and an automatic control system.

● Can be linked with a three-sided book cutting machine to form a completed book block shaping line that can previsely cut book blocks and deliver them to subsequent workbenches.

Technical Data:

Max. operating speed |

60 books/min |

Power consumption |

26.5 KW |

Max book block size |

430×320 mm |

Standard voltage |

3PH 380V 50Hz |

Min book block size |

125×100 mm |

Air consumption (external supply) |

0.35 m3 /min 8 bar |

Book block thickness |

4-70 mm |

Max. pressure |

100 KN |

Thickness of paper folding |

60-150g |

Dimensions (length x width x height) |

22800×3850×1735 mm |

Thickness of single paper |

120-300g |

Gross Weight |

10500 kg |

Max Drying temperature |

150℃ |

|

|

|

L H S Max. size 300 430 70mm Min. size 100 125 4mm |

AUSCP SL60 |

|

Introduction video